Where Did The Great Motorbike Creation Start?

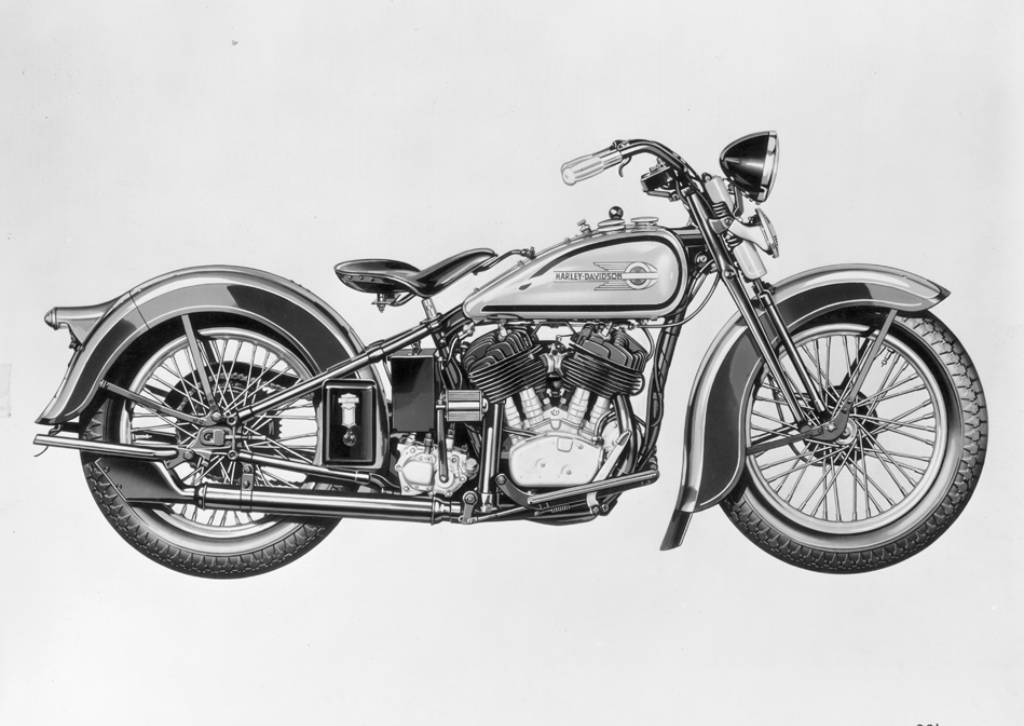

It’s over 115 years since Harley-Davidson produced their first motorcycles for the public.

It all started with some backyard engineering between childhood friends William Harley and Arthur Davidson.

Both worked at the same firm with Harley being an apprentice draughtsman and Davidson as a patternmaker, had a similar idea of fitting a small motor to a bicycle frame to take the effort out of riding around Milwaukee.

Their first effort wasn’t a huge success which was a 25ci engine but the flywheel was too small so the engine didn’t create enough torque.

All of the work was done in a neighbour’s shed, but by the time they were ready to launch their motorcycle in 1903, they had moved to the new ‘factory’, a 10ft by 15ft shed built by Arthurs’s dad William C Davidson.

The first Harley-Davidson was sold and in 1913 Harley advertised that it was still in service and had travelled 100,000 miles using its original bearings.

How Did It Go Soon After The First Release?

With the immediate success of their motorcycles they quickly outgrew their original premises and in 1904 the shed size was doubled along with their first official employee being hired outside of the families in 1905.

The following year saw the next progression with a 28 by 80ft factory built just a block from the Harley and Davidson family home where the H-D headquarters now stand on Juneau Ave – this time thanks to a loan from an uncle.

With the framework up they were then informed by the railroad that they were encroaching on the right of way, so instead of having the new building demolished, they found ten burly blokes to pick the whole lot up and move it a few feet to a safer position.

Don’t you just love the good old days when solutions were simple.

Several other additions were made until the first brick building was erected in 1910 with a H-D workforce now numbering 147.

Juneau Ave in Milwaukee is without a doubt the spiritual home of Harley-Davidson, and the site of that first backyard shed/factory is now interestingly the Miller Brewery.

But H-D has plenty of other plants that most people tend to ignore.

The first to come along was in 1947 when the Motor Co. held their National Dealer Conference at the then newest of plants at Capitol Drive Wauwatosa.

Originally it was used for manufacturing parts which were then shipped off to Juneau Ave for assembly.

I’ve been lucky enough to have had a tour through this facility during the 100th Anniversary Tour when it was in full swing assembling engines, but unfortunately this site ceased operations in 2011 and was last used to supply Sportster powerplants.

Entry To Motorcycle World Championship

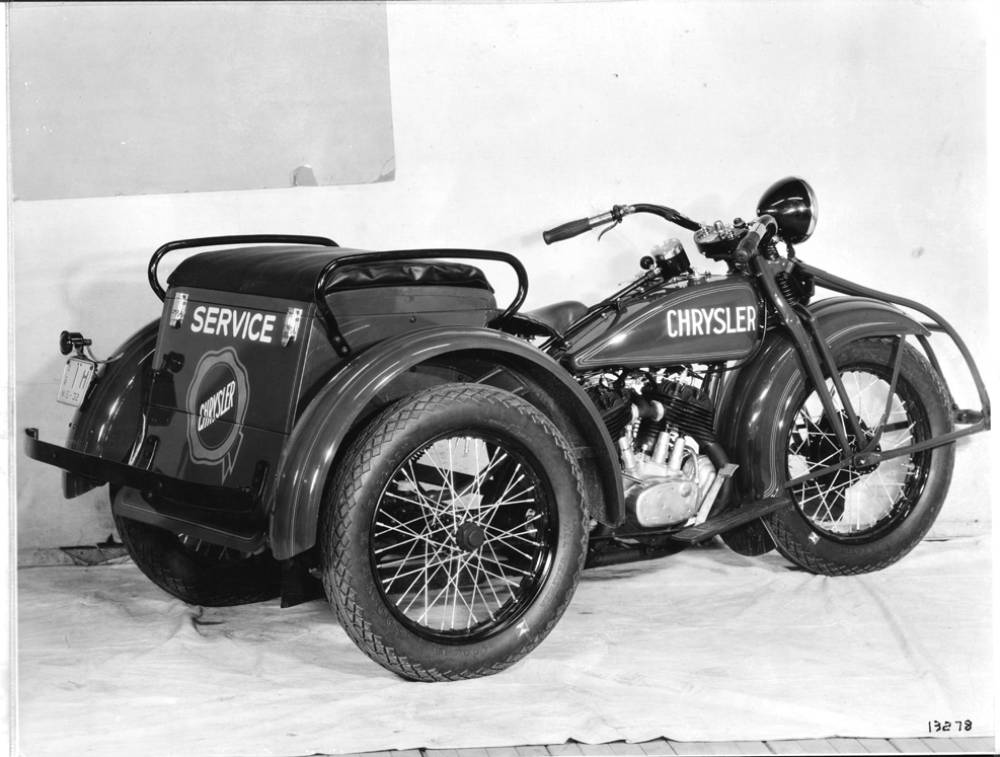

1962 saw Harley-Davidson diversify their business after purchasing a fiberglass boat plant at Tomahawk Wisconsin in an effort to take advantage of the increasing use of fiberglass in the motorcycle industry.

This led to them moving into the Golf Cart business as well as making paniers for their motorcycles.

1962 is also the year H-D purchased the motorcycle division of Aeronautica Macchi, an Italian aircraft and motorcycle manufacturer specialising in small single cylinder motorcycles.

This was aimed at taking on the smaller commuter bikes being imported from Europe, Britain and of course Japan.

Rebranded Aermacchi Harley-Davidson, it was the Aermacchi H-Ds that won the 250cc and 350cc World Championships in 1974, ‘75 and ‘76.

Aermacchi was eventually sold to Cagiva in 1978.

Harley-Davidson Under American Machine And Foundry

It was during the AMF years that expansion really took on a new meaning for Harley-Davidson and for the first time they purchased a factory outside of Wisconsin on the York Pennsylvania where the motorcycles were assembled.

That was in 1973 and the plant is still on operation today.

In 1981 13 senior H-D executives, including Willie G Davidson and his father John, signed a letter of intent to purchase Harley-Davidson from AMF and six months later the deal was complete – for the first time in 1982 the company was finally out from under the banner of AMF.

The AMF years were both good and bad for Harley-Davidson.

AMF went through with a giant broom modernizing the company with the intent on looking for the best product for the best price, hence the deal for the Japanese made Showa front forks.

Many of the workers weren’t happy about the decision with some even going so far as sabotaging the bikes to show their dislike.

But without AMF the company would have gone under or at least been subject to a hostile takeover.

Long Wait Time For Motorcycle Customers

The great thing about this is that most of the development work on the 80ci Evolution motor was complete, which really was the start of the modern H-D story.

With a more modern and stronger product, Harley-Davidson motorcycles became very sought after creating long waits for delivery across the world.

In fact, some customers in the USA even had to wait longer than customers in Australia!

To cope with this boom Harley opened another engine facility in the mid-1990s at Menomonee Falls Wisconsin to take on the building of the FL big twin engines and transmissions while the Sportster engines and gearboxes remained with the Capitol Drive plant.

And for the second time in its manufacturing history, H-D moved some assembly lines out of state creating a 330,000 sq. ft. plant in Kansas City Missouri to build Sportsters and later the V-Rod. H-D closed this plant in May 2019 due to a downfall in motorcycle sales.

Harley-Davidson Parts And Their Assembling

And I’ll bet you didn’t know that Harley-Davidson had a factory in Australia.

It was in Adelaide and was specifically to make H-Ds alloy wheels and operated as a wholly owned subsidiary of H-D – but this too has now closed after supplying wheels for over 10 years. Most manufacture of parts, including wheels are now done in China.

There are other also overseas plants operated by Harley-Davidson in Brazil and India.

Both operate as TKD facilities (total Knock Down) where essentially the whole bike is shipped in parts before being assembled in these factories.

Obviously the decision was a no-brainer, especially considering by having a local component it allows them to avoid the high tariffs imposed on vehicles – the local component is achieved by using local residents to work at the assembly facilities – dropping the extra 25-50% tax.

Another factory is also scheduled to open soon in Thailand to take advantage of the same loophole in the import taxes.

Overall Harley-Davidson motorcycles are still made/assembled in the USA before parts such as wheels and suspension are imported and fitted to locally manufactured frames and engines which is common practice for the entire Automotive industry whether it be Australian, American or otherwise.

The idea is to make a good product at an affordable price, and that way everyone wins.

Shovelhead History will be coming soon..

Read our LiveToRide publications for more great information and keep your riding passion alive.