Harley-Davidson with AMF

HARLEY-DAVIDSON Shovelhead engine is definitely loved by enthusiasts but also much maligned by those who subscribe to the theory that Harleys are unreliable running oil leaks.

The problem was that at the start of the Shovelhead era Harley-Davidson was floated in 1965 by the families, but was not doing so well.

As operation costs began to cripple the company, in 1969 it was offered for sale to American Machine and Foundry (AMF), who were in the leisure industry market and a better fit than the hostile takeover that was proposed.

If the hostile takeover had gone ahead the company would have been broken up and sold off as individual pieces ending Harley-Davidson completely.

The Davidson family would have none of that which is why the AMF option was offered.

Harley-Davidson with American Machine And Foundry

The AMF era was a major time of rebuilding and turbulence for Harley-Davidson.

AMF looked at all aspects of the business including the parts purchasing process, quickly determining that better quality parts could be bought cheaper from overseas.

The front and rear suspension is a great example as the units being used were not as good as the suspension units offered by Showa (Japan) and when purchased in bulk were much cheaper.

Understandably this caused friction between the staff and the company as many resented the fact that ‘imported parts’ were being fitted to American motorcycles.

There were union actions and even some reported staff sabotage during this period of time including the story of a sandwich being found inside a brand new bike’s gearbox during the pre-sale check.

It was no surprise to see that during the early 70’s these changes resulted in various reliability problems.

Parts Replacement For Better Efficiency!

The H-D Shovelhead began life in 1966 using the bottom end of the previous Panhead motor fitted with an updated set of heads called the PowerPak, which were essentially a set of Sportster heads made in aluminium.

These heads featured a shallower combustion chamber which kept the head cooler while the compression was increased from 6:1 to 8:1 with domed pistons.

The rocker shafts mounts were now part of the rocker box cover but the displacement remained at 74 cubic inches.

The Panhead bottom end also ran a generator to supply charge to the battery, however this was essentially robbing the bike of some power as it was gear driven.

So a new cone bottom end was devised for the 1970 models which replaced the old fashioned generator with an alternator.

The stator was fixed to the left side of the crankcase and the magnetic rotor was on a splined shaft that spun the primary drive.

At the same time the breaker points were moved into the nose of the cone as their usual mount on the casing was now non-existent.

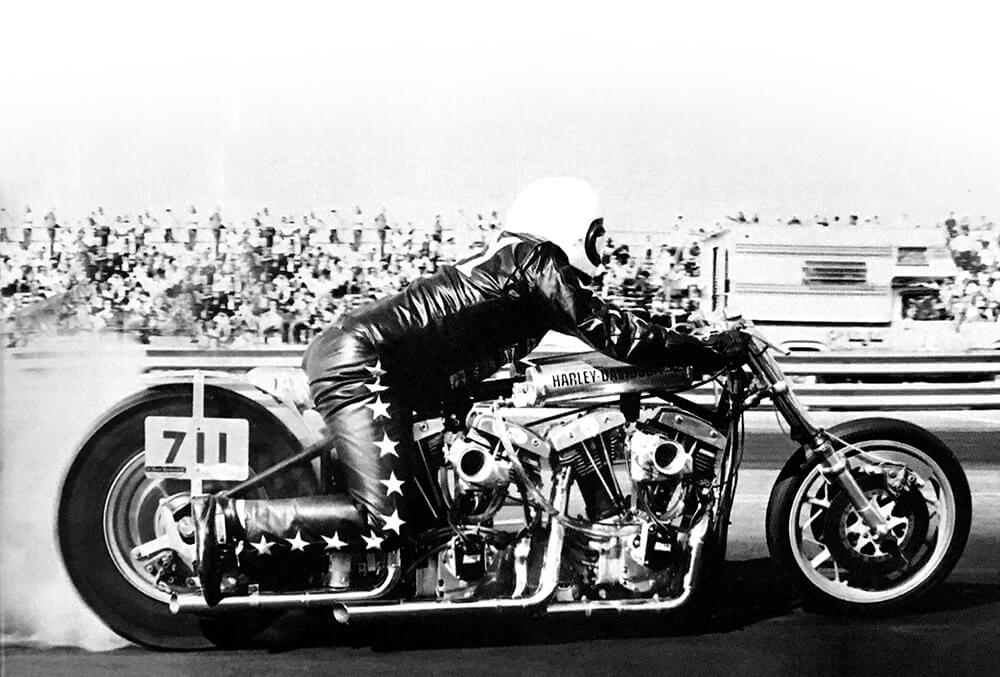

FX line of motorcycles

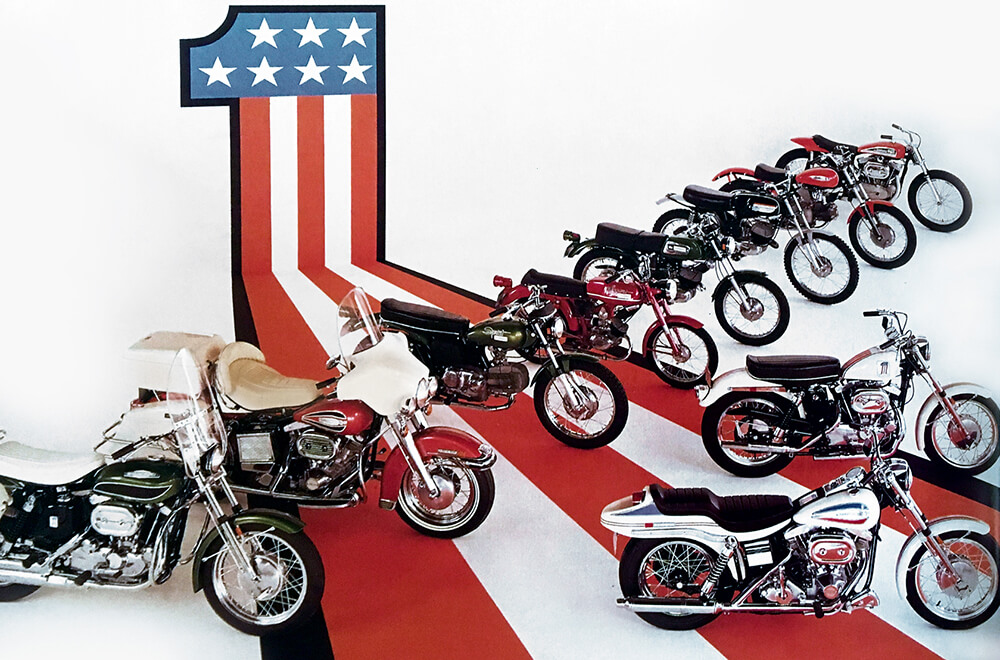

Up until 1971 the only Harley-Davidson motorcycles you could buy were the FLH, Sportsters and the range of small Italian made Sprint models.

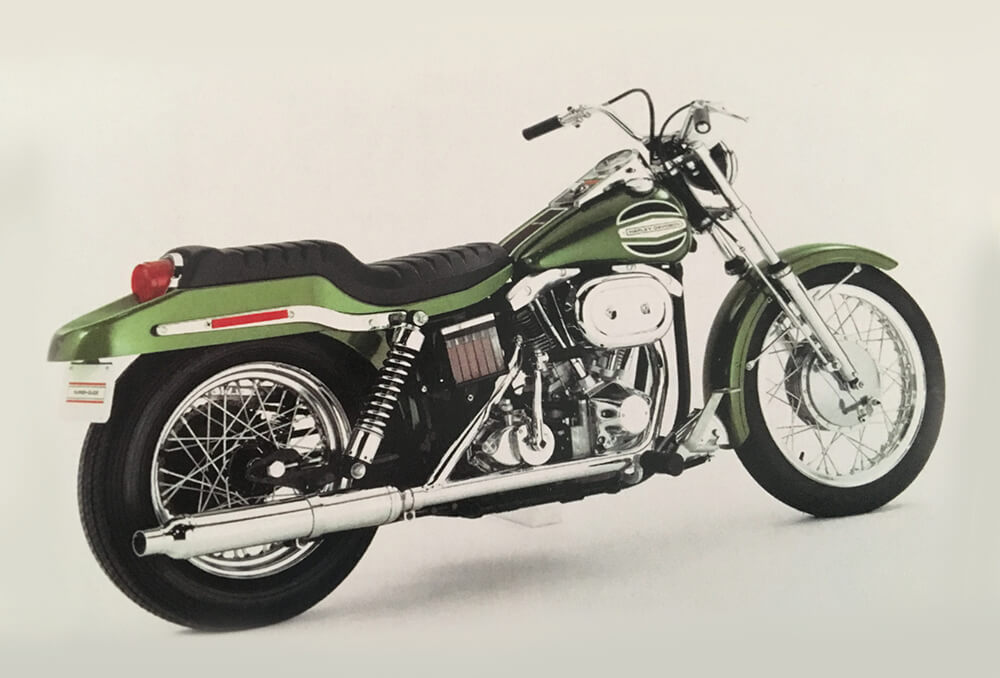

The FLH was the only Big Twin available but Willie G Davidson had plans and unveiled the first factory custom, the FX Super Glide that mated a Sportster style front end with a Big Twin frame and drivetrain.

He also took a Chevy tail light and designed the boat tail rear guard to give it a different look.

On release it wasn’t as well received as many didn’t like the look of the boat tail and sales were slow.

But what it did introduce was the FX line of motorcycles, with the FX signature still in operation today.

In fact, the original FX Super Glide is now a much sought after collector’s item.

Impact Of US Fuel Crisis on Motorcycles

During the mid-1970s the USA went through a fuel crisis where the octane rating was lowered and fuel was very inconsistent, all of which led to overheating on most air-cooled motorcycles.

It was around this time that the US government regulated that all new vehicles were to be tuned lean (air rich rather than fuel rich), which had an adverse effect especially on Harley V-twins as they had always run rich to assist with cooling the engine.

Now running lean meant extra heat and with a mix of cast iron barrels and alloy heads the expansion became a problem by destroying gaskets and creating oil leaks.

There were also problems with the exhaust mounts as they were only mounted in the heads with a single bolt.

It was around this time H-D started to think about a replacement motor, but it would take another 10 years for that to be released.

First Factory Custom Of Motorcycle

AMF were pushing H-D to levels of manufacture that they hadn’t seen since WWII with a concept of build it, sell it and then fix the problems at the dealership.

All of this wasn’t good for the reputation of H-D and, as stated before, the manufacturing staff were not happy and neither was much of the H-D management.

But this was still late 1970s.

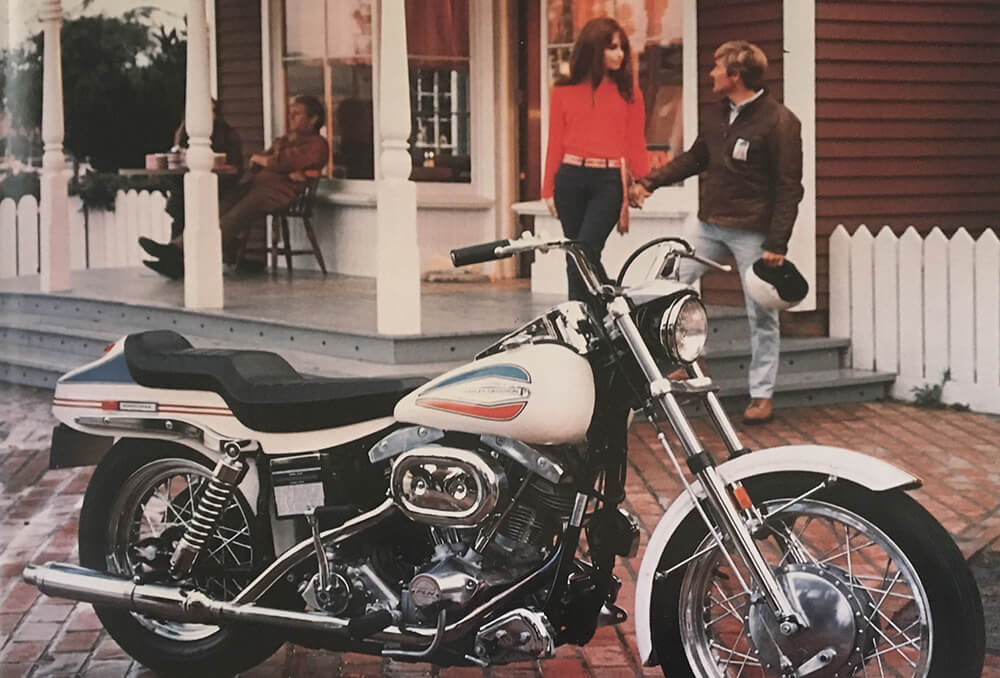

Harley didn’t sit still with the FX line and in 1977 introduced the FXS Low Rider, a model the company really regarded as the first factory custom.

With its low seat height, drag bars, highway pegs, two into one exhaust and twin gauges on the tank it had a completely different appearance to the standard FX.

Willie G knew he had hit a home run with this one, especially after he and another H-D employee rode two of them to Daytona getting enthusiastic results from all who saw them.

Many thought they were one-off customs, which is why the dealer network were more than happy to have them in the showrooms.

Observed A Rise In Motorcycle Engine Capacity

1978 saw an increase in engine capacity to 80ci (well really 81.7ci but H-D rounded it down to 80) and the 80ci engine delivered its power a little more smoothly than the 74ci engine.

The stroke on the 80 was longer at 4.250in (vs 3.96875) and with the bore at 3.4975in (vs 3.4375in) which provided a slower revving motor, and by 1980 it was the only big twin available in a brand new H-D motorcycle.

Expanding the FX line in 1979 was the FXEF Fat Bob which was a cross between a Super Glide and a Low Rider and then in 1980 the Wide Glide was released, which was the bike I personally wanted, especially with its custom paint and 80ci engine all blacked out.

H-D Released Sturgis FXSB Motorcycle

Apart from the Wide Glide in 1980 H-D also introduced its new rubber mounted frame in the form of the FLT featuring an 80ci motor and five speed gearbox.

This was a revolutionary motorcycle for H-D and the start of the FXR and FLHT range of motorcycles to follow in the next few years.

And to celebrate 50 years of the Sturgis Motorcycle Rally, H-D released the Sturgis FXSB featuring their new Kevlar rear belt drive and a one-inch primary belt.

As it turns out the primary belt wasn’t up to handling the pulses of the 80 cube motor and were renowned for breaking, with many being replaced with the standard triplex chain primary drive.

H-D End With AMF

In 1981 the gang of thirteen led a buy-back from AMF who had been disappointed with the fact that Harley-Davidson motorcycles weren’t selling as fast as they had expected.

Since 1975 AMF had trimmed their investment in the motorcycle division and hadn’t worked on developing any innovations or future development for some time.

This led to the infamous buy-back by Vaughn Beals, John Davidson and Willie G along with 10 other directors and company officials.

Houses were mortgaged, business loans arranged and AMF agreed to the sale.

Harley-Davidson Praised For Its Methods

In 1982 H-D was back in private hands and they celebrated by releasing the FXR/FXRS range of bikes which featured a special front fender badge on all 1982 models.

Also in 1982 H-D started its materials as it needed a program where parts would arrive just in time to be fitted

This saved the company a lot of money and despite many considering it to be a Japanese style of production, it had been used by most companies during the war years but put aside in the prosperous years of the 1950s and 1960s.

H-D became so good at this method they were held up as a shining example to all other US manufacturing companies and taught many of them how it was achieved.

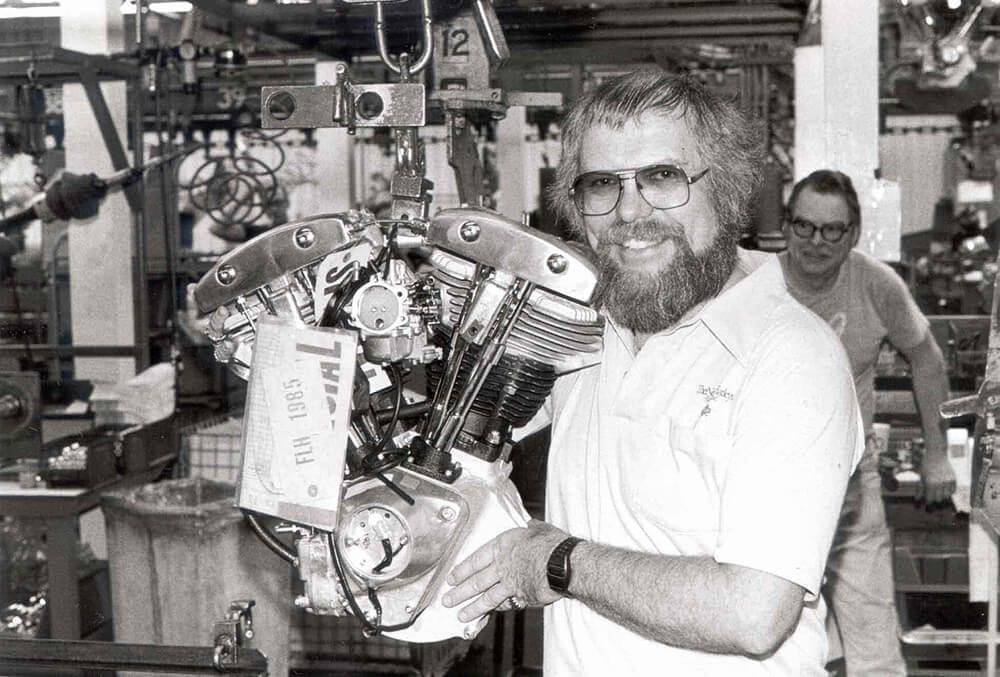

The Shovelheads final hurrah!

The Shovelheads last hurrah was when it ran alongside the Evolution engine in 1984.

H-D released the brand new Softail featuring the all alloy 80ci Evo which also featured in the Low Rider and the FLT/FLHT motorcycles.

The Shovel motor had performed well for 18 years and was finally pensioned off for good in 1985.

During the reign of the Shovelhead motors we saw disc brakes fitted to all H-D motorcycles, five-speed gearboxes make an appearance, electronic ignition became the norm and of course CV carburetors fitted for better fuel delivery.

The Shovelhead was the mainstay of the early motorcycle custom scene in Australia and still has a wide following.

Yes, it had its troubles due to poor fuel and the difference in expansion rates of cast iron and oil, but a well maintained Shovelhead was capable of long distance travel provided of course you used a liberal amount of Loctite on all fasteners.

But despite all its problems, the cone Shovel still remains my favourite and arguably the best looking Harley motor ever built

And I’ll bet you didn’t know that Harley-Davidson had a factory in Australia.

Harley-Davidson Factories In Other Countries!

It was in Adelaide and was specifically to make H-Ds alloy wheels and operated as a wholly owned subsidiary of H-D – but this too has now closed after supplying wheels for over 10 years.

Most manufacture of parts, including wheels are now done in China.

There are also other overseas plants operated by Harley-Davidson in Brazil and India.

Both operate as TKD facilities (total Knock Down) where essentially the whole bike is shipped in parts before being assembled in these factories.

Obviously the decision was a no-brainer, especially considering by having a local component it allows them to avoid the high tariffs imposed on vehicles

The local component is achieved by using local residents to work at the assembly facilities – dropping the extra 25-50% tax.

Another factory is also scheduled to open soon in Thailand to take advantage of the same loophole in the import taxes.

Overall Harley-Davidson motorcycles are still made/assembled in the USA before parts such as wheels and suspension are imported and fitted to locally manufactured frames and engines which is common practice for the entire Automotive industry whether it be Australian, American or otherwise.

The idea is to make a good product at an affordable price, and that way everyone wins.

Read more wonderful information in our LiveToRide magazines to keep your riding love alive.

![High-Res_JPG_-_HD38399[1]](https://livetoride.com.au/wp-content/uploads/2024/03/High-Res_JPG_-_HD383991-1.jpg)

![High-Res_JPG_-_HD39520[1]](https://livetoride.com.au/wp-content/uploads/2024/03/High-Res_JPG_-_HD395201-1.jpg)

![High-Res_JPG_-_HD36422[1]](https://livetoride.com.au/wp-content/uploads/2024/03/High-Res_JPG_-_HD364221.jpg)

![High-Res_JPG_-_HD38867[1]](https://livetoride.com.au/wp-content/uploads/2024/03/High-Res_JPG_-_HD388671.jpg)